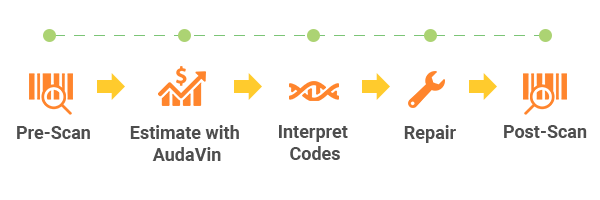

Over the last couple of years, scanning technology has moved from the backburner to the forefront of top-of-mind issues associated with accurate vehicle repairs. At least in the U.S., there seems to be an emerging consensus that both pre and post repair scanning (PPS) is required on the majority, if not all repair jobs.

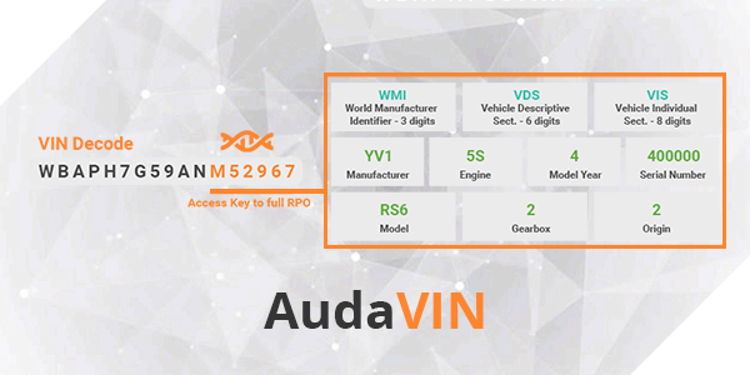

Scanners pull data from the CPE/CPU to determine the engine and trim configuration of the vehicle. However, in some cases, the interpretation of scan codes can be difficult, since OEM scan tools do not contain the factory build data. Even something as basic as the transmission type may not be identified by the data. While a technician can easily identify this feature on car or truck, optional equipment such as side object detection modules are more difficult. If the vehicle is not equipped with one of these options, the scanner will report that there was no communication with the module. There are two interpretations: the particular optional equipment is absent from the vehicle, or that the option is present but the module is not functioning properly.

AudaVIN eliminates the guesswork from this task for 19 manufacturers that provide AudaVIN data —Including Toyota, Ford, Mercedes—which represent over half of all Canadian vehicles sold today. After the pre-scan, the estimating process identifies all factory added optional equipment. This allows the estimator to easily identify and enter all required repair tasks on the estimate.

The final step is the post scan (or scans) to ensure clearance of all reset or recalibrated codes, with the knowledge that one has accounted for all factory-added equipment.